Professional China Optical Ethernet Transceiver - Gigabit fiber optic transceiver (one optical and four electricity) – Changfei Optoelectronics

Professional China Optical Ethernet Transceiver - Gigabit fiber optic transceiver (one optical and four electricity) – Changfei Optoelectronics Detail:

product description:

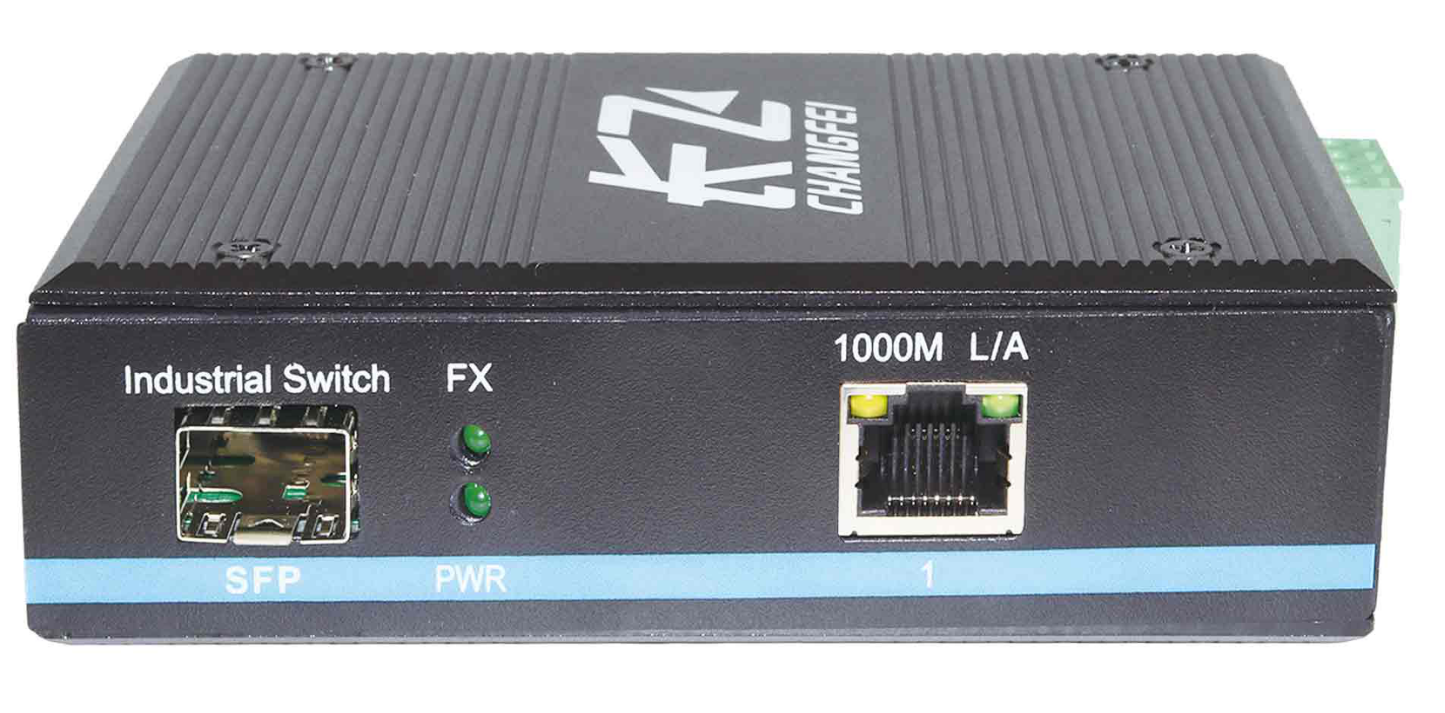

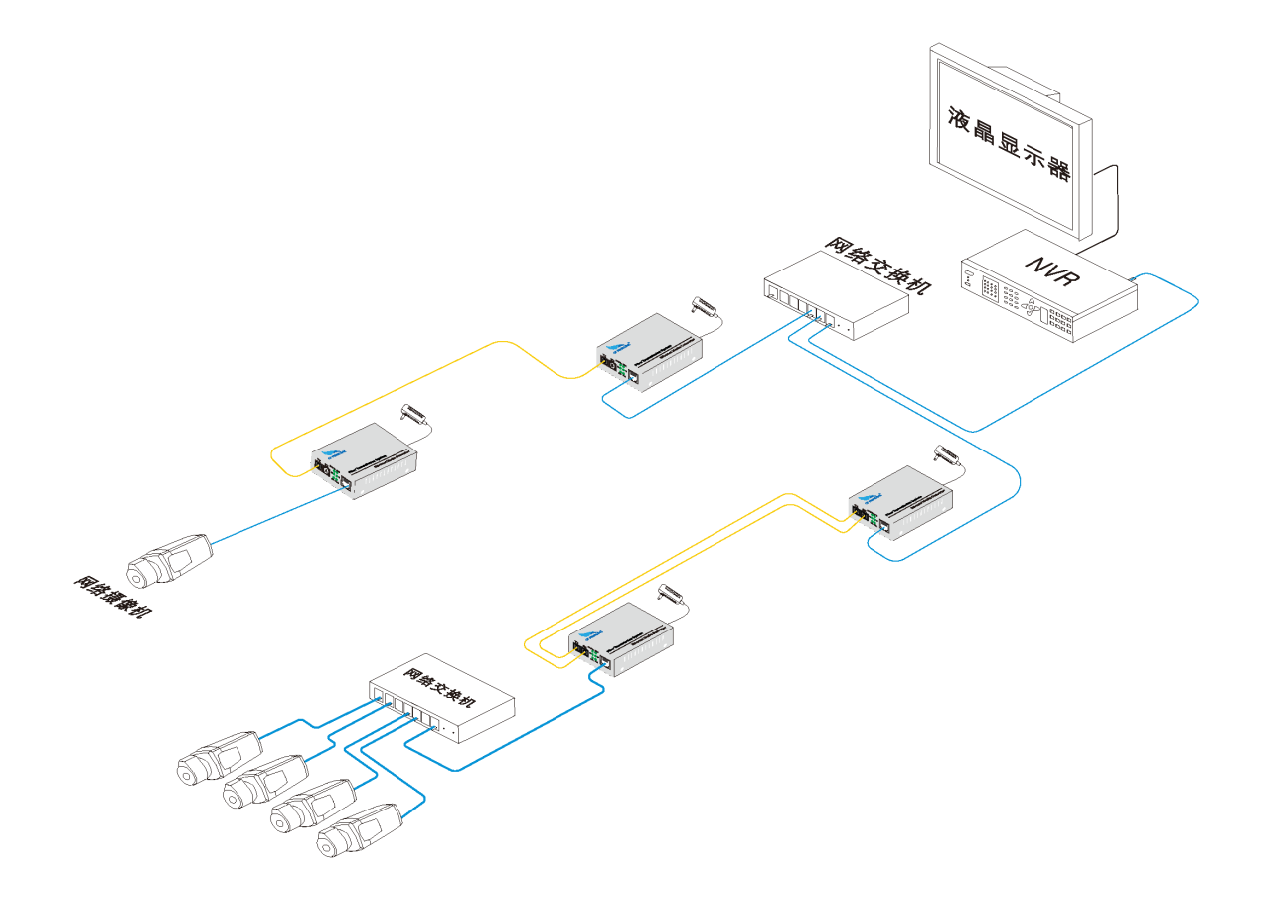

This product is a gigabit fiber optic transceiver with 1 gigabit optical port and 4 1000Base-T(X) adaptive Ethernet RJ45 ports. It can help users realize the functions of Ethernet data exchange, aggregation and long-distance optical transmission. The device adopts fanless and low power consumption design, which has the advantages of convenient use, small size and simple maintenance. The product design conforms to the Ethernet standard, and the performance is stable and reliable. The equipment can be widely used in various broadband data transmission fields such as intelligent transportation, telecommunications, security, financial securities, customs, shipping, electric power, water conservancy and oil fields.

| network port | 2×10/100/1000Base-T Ethernet ports | |

| Fiber port | 1×1000Base-FX SC interface | |

| Power interface | DC | |

| led | CF-1024GMW-2 | |

| rate | 4×10/100/1000Base-T Ethernet ports | |

| light wavelength | 1×1000Base-FX SC interface | |

| web standard | DC | |

| Transmission distance | PWR, FDX, FX, TP, SD/SPD1, SPD2 | |

| transfer mode | 100M | |

| IP rating | 1310nm | |

| Backplane bandwidth | IEEE802.3, IEEE802.3u, IEEE802.3z | |

| packet forwarding rate | 2KM | |

| Input voltage | full duplex/half duplex | |

| Power consumption | IP30 | |

| Operating temperature | 10Gbps | |

| storage temperature | 7.44Mpps | |

| Working humidity | DC 5V | |

| Cooling method | Full load<5W | |

| Dimensions (LxDxH) | -20℃ ~ +70℃ | |

| weight | -15℃ ~ +35℃ | |

| Installation method | 5%-95% (no condensation) | |

| Certification | fanless | |

| LED indicator | condition | meaning |

| SD/SPD1 | Bright | The current electrical port rate is gigabit |

| SPD2 | Bright | The current electrical port rate is 100M |

| extinguish | The current electrical port rate is 10M | |

| FX | Bright | Optical port connection is normal |

| flicker | Optical port has data transmission | |

| TP | Bright | The electrical connection is normal |

| flicker | The electrical port has data transmission | |

| FDX | Bright | The current port is working in full duplex state |

| extinguish | The current port is working in half-duplex state | |

| PWR | Bright | Power is OK |

Optical fiber fusion, small knowledge of optical fiber splicing steps

Fiber splicing:

1. The principle that should be followed for optical fiber connection is: when the number of cores is equal, it should be connected with the corresponding color optical fiber in the bundle tube.

2. There are three methods of optical fiber splicing: fusion splicing, active connection, and mechanical connection. Most of the projects are used in the welding method. The advantages of using this welding method are that the contact loss is small, the reflection loss is large, and the reliability is high.

Little knowledge of fiber optic connection steps:

Step 1: Strip the optical cable and fix the optical cable into the splice box. Be careful not to injure the bundle tube, take about 1m for the stripping length, wipe the ointment clean with toilet paper, and put the optical cable into the splice box. When fixing the steel wire, it must be pressed tightly without loosening.

Step 2: Split the fiber through the heat shrink tube. Separate the fibers of different bundles and colors and pass them through the heat-shrinkable tube. The stripped fiber is very fragile, use heat shrink tubing to protect the fiber splice.

Step 3: Turn on the power of the Furukawa S176 fusion splicer, use the preset 42 programs to splicing, and remove the dust in the fusion splicer in time during and after use, especially the fixture, the dust and dust in the mirror and V-shaped groove. Fiber is broken. The optical fibers used in CATV include conventional single-mode fiber and dispersion-shifted single-mode fiber, and the operating wavelengths are also 1310nm and 1550nm.

Step 4: Fabricate the fiber end face. The quality of the fiber end face will directly affect the quality of the connection, so it is necessary to make a qualified end face before fusion splicing. Use a special wire stripper to peel off the coating layer, then wipe the bare fiber with alcohol-dipped cleaning cotton several times with moderate force, and then use a precision fiber cutter to cut the fiber. For 0.25mm (outer coating) fiber, The cutting length is 8mm-16mm. For 0.9mm (outer coating) fiber, the cutting length can only be 16mm.

Step 5: Place the fiber. Put the optical fiber in the V-shaped groove of the fusion splicer, carefully press the optical fiber pressure plate and the optical fiber clamp, set the position of the optical fiber in the pressure plate according to the fiber cutting length, close the windshield, and the fusion can be automatically completed in 11 seconds.

Step 6: Remove the fiber and heat the heat shrinkable tube with a heating furnace. Open the draft shield, take the fiber out of the fusion splicer, place the heat shrink tube in the center of the bare fiber, and place it in a heating furnace for heating. Tube is 85 seconds.

Step 7: Fix the fiber coil. Coil the spliced optical fiber onto the optical fiber receiving tray. When coiling the fiber, the larger the radius of the coil and the larger the radian, the smaller the loss of the entire line.

Step 8: Seal and Hang. The field connection box must be sealed to prevent water from entering.

Precautions for fusion splicing of fiber optic cables

First, clean, the inside and outside of the optical fiber fusion splicer, the optical fiber itself, the most important parts are the V-groove, the optical fiber presser and other parts.

2. When cutting, ensure that the cutting end face is 89°±1°, which is approximately vertical. During the process of placing the cut fiber in the designated position, the end face of the fiber should not touch any place. If it touches, we need to clean and cut it again: Emphasis Clean first, then cut!

3. When placing the optical fiber in its position, neither too far nor too close, 1/2 place, proficiency!

Product detail pictures:

Related Product Guide:

The company upholds the philosophy of "Be No.1 in quality, be rooted on credit and trustworthiness for growth", will continue to serve old and new customers from home and overseas whole-heatedly for Professional China Optical Ethernet Transceiver - Gigabit fiber optic transceiver (one optical and four electricity) – Changfei Optoelectronics , The product will supply to all over the world, such as: Angola, Belize, Congo, At present our sales network is growing continually, improving service quality to meet customer's demand. If you are interested in any products , please contact us at anytime. We are looking forward to forming successful business relationships with you in near future.

A good manufacturers, we have cooperated twice, good quality and good service attitude.